Ngaphantsi kweemeko zokuqina, ubunzulu obukhulu bokusika busetyenziselwa ukukhwabanisa ukunciphisa inani lokupasa kunye nokuphucula imveliso yomsebenzi;ukugqiba, ubunzulu obuncinci bokusika busetyenziswa ngokubanzi ukufumana umgangatho ophezulu womphezulu.Ukuchaphazela ukuchaneka kokugqibela komatshini kunye nokusebenza kakuhle komatshini wokusebenza, ukongeza kwizizathu zesixhobo somatshini we-CNC ngokwawo, kufuneka kwakhona kubandakanye izicwangciso zendlela yomatshini, ukukhethwa kwezixhobo kunye nofakelo oluchanekileyo, ukhetho olufanelekileyo lwexabiso lokusika, izakhono zokucwangcisa, kunye nokukhawuleza. ulawulo lokuchaneka komda.ingqwalasela ebanzi.

1. Izakhono zokucwangcisa

Inkqubo ye-NC ngowona msebenzi usisiseko womatshini weNC.I-pros and cons of the workpiece machining programme ichaphazela ngokuthe ngqo ukuchaneka kokugqibela komatshini kunye nokusebenza kakuhle kwesixhobo somatshini.Inokuqala kwimiba emininzi, njengosetyenziso olukrelekrele lweenkqubo zendalo, ukuncitshiswa kweempazamo ezongezelekayo zenkqubo ye-CNC, kunye nokusetyenziswa okubhetyebhetye kweenkqubo eziphambili kunye neenkqutyana.

1. Ukusetyenziswa okuguquguqukayo kwenkqubo engundoqo kunye nenkqutyana

Ekuqhutyweni kweembumba eziyinkimbinkimbi, ngokuqhelekileyo zicutshungulwa ngendlela yokubumba enye kunye neziqwenga ezininzi.Ukuba kukho iimilo ezininzi ezifanayo kubumba, ubudlelwane phakathi kwenkqubo engundoqo kunye nenkqutyana kufuneka isetyenziswe ngokuguquguqukayo, kwaye inkqubo engaphantsiyo kufuneka ibizwe ngokuphindaphindiweyo kwinkqubo engundoqo de kugqitywe inkqubo.Ayinakuqinisekisa kuphela ukuhambelana kwemilinganiselo yokucubungula kodwa iphucula nokusebenza kwayo.

2. Ukunciphisa impazamo eyongezelekayo yesistim ye-CNC

Ngokuqhelekileyo, indlela yokunyuka isetyenziselwa ukucwangcisa i-workpiece, esekelwe kwindawo yangaphambili.Ngale ndlela, ukuphunyezwa okuqhubekayo kweenkqubo zamacandelo amaninzi ngokuqinisekileyo kuya kuvelisa impazamo ethile eyongezelekayo.Ngoko ke, zama ukusebenzisa inkqubo epheleleyo xa udwelisa inkqubo, ukwenzela ukuba icandelo ngalinye leprogram lisekelwe kwi-workpiece.Imvelaphi yibenchmark, ukwenzela ukuba impazamo eqokelelweyo yenkqubo ye-CNC ingancitshiswa kwaye ukuchaneka komatshini kunokuqinisekiswa.

Ukuchaneka koMatshini kusetyenziswa ikakhulu ukuvelisa iimveliso, kwaye ukuchaneka komatshini kunye nempazamo yomatshini ngamagama asetyenziselwa ukuvavanya iiparamitha zejometri zomgangatho owenziwe ngomatshini.Nangona kunjalo, iiparamitha zokwenyani ezifunyenwe ngayo nayiphi na indlela yomatshini aziyi kuchaneka ngokupheleleyo.Ukususela kumsebenzi wecandelo, ngokude nje ukuba impazamo yomatshini ingaphakathi kwibala lokunyamezela elifunwa ngumzobo wenxalenye, kuthathwa ukuba ukuchaneka komatshini kuqinisekisiwe.

Ukuchaneka komatshini kubhekiselele kwiiparamitha zejometri zangempela (ubungakanani, imilo kunye nesikhundla) senxalenye emva komatshini.Umahluko phakathi kwabo ubizwa ngokuba yimpazamo yomatshini.Ubungakanani bempazamo yomatshini bubonisa inqanaba lokuchaneka komatshini.Okukhona impazamo inkulu, okukhona kusezantsi ukuchaneka komatshini, kunye nempazamo encinci, kokukhona kuphezulu ukuchaneka komatshini.Oku kulandelayo yintshayelelo emfutshane kwiindlela zokuphucula ukuchaneka komatshini wezixhobo zokusebenza:

1. Lungisa inkqubo yenkqubo

I-1): Indlela yokusika isilingo ihlengahlengiswa ngokusikwa kwesilingo - ubungakanani bokulinganisa - ukulungelelanisa umlinganiselo wokulunywa kommese wesixhobo - ukusika ngokusika - zama ukusika kwakhona, njalo njalo de ubungakanani obufunwayo bufikelelwe.Le ndlela inomgangatho ophantsi wemveliso kwaye isetyenziswa ikakhulu kwimveliso yebhetshi encinci.

2): Indlela yokulungelelanisa ifumana ubungakanani obufunekayo ngokulungisa kwangaphambili izikhundla ezihambelana nesixhobo somatshini, ukulungiswa, i-workpiece kunye nesixhobo.Le ndlela inemveliso ephezulu kwaye isetyenziselwa imveliso yobuninzi.

2. Nciphisa impazamo yesixhobo somatshini

--Ukuchaneka komjikelezo wokuthwala kufuneka kuphuculwe

①Khetha ukuchaneka okuphezulu kweebheringi eziqengqelekayo

②Ukusebenzisa i-oyile eninzi echanekileyo eguquguqukayo yeebheringi zoxinzelelo

③Ukusebenzisa iibheringi ze-hydrostatic ezichanekileyo

--Ukuphucula ukuchaneka kwezincedisi ezineebheringi

①Phucula ukuchaneka komatshini wemingxuma yenkxaso yeebhokisi kunye neejenali ze-spindle

②Phucula ukuchaneka komatshini womphezulu wokukhwelana ngokuthwala

③ Linganisa kwaye ulungelelanise uluhlu oluphumayo lweradial lwamalungu ahambelanayo ukwenza imbuyekezo yempazamo okanye ukulinganisa

--Layisha kwangaphambili ngokufanelekileyo ukuthwala okuqengqelekayo

①Inokuphelisa umsantsa

②Ukwandisa ukuqina kokuthwala

③ I-Homogenization yempazamo yesiqalelo esiqengqelekayo

--Ukuchaneka kokujikeleza kwe-spindle akubonakali kwi-workpiece

3. Nciphisa impazamo yothumelo lwekhonkco lothumelo

(1) Inani leenxalenye zothumelo lincinci, ikhonkco lothumelo lifutshane, kwaye ukuchaneka kokudluliselwa kuphezulu.

(2) Ukusetyenziswa kokudluliselwa kwesantya ngumgaqo obalulekileyo wokuqinisekisa ukuchaneka kothumelo, kwaye isibini sothumelo sisondele ekupheleni, umlinganiselo omncinci wothumelo kufuneka ube.

(3) Ukuchaneka kwesiqwenga sokuphela kufuneka sibe phezulu kunezinye iindawo zokuhambisa

Okwesine, ukunciphisa ukunxiba izixhobo

(1) Isixhobo masilolwe kwakhona phambi kokuba isayizi yesixhobo iguge ifikelele kwinqanaba lokuguga ngokukhawuleza

(2) Khetha ioli yokusika ekhethekileyo yokuthambisa ngokupheleleyo

(3) Isixhobo sesixhobo kufuneka sihlangabezane neemfuno zenkqubo

5. Ukunciphisa uxinzelelo kunye nokuguqulwa kwenkqubo yenkqubo

(1) Ukuphucula ukuqina kwenkqubo, ngakumbi ukuqina kwamakhonkco abuthathaka kwinkqubo yenkqubo.

(2) Nciphisa umthwalo kunye neenguqu zawo

6. Ukunciphisa i-thermal deformation yenkqubo yenkqubo

(1) Nciphisa ukuveliswa kobushushu kumthombo wobushushu kwaye ukwahlula umthombo wobushushu

(2) Intsimi yeqondo lokushisa elilinganayo

(3) Yamkela isakhiwo sesixhobo somatshini esifanelekileyo kunye nebhentshi yendibano

(4) Ukukhawulezisa ukufezekisa ukulingana kokutshintshwa kobushushu

(5) Lawula ubushushu bendawo

Isixhenxe, ukunciphisa uxinzelelo olushiyekileyo

(1) Ukwandisa inkqubo yokunyanga ukushisa ukuphelisa uxinzelelo lwangaphakathi;

(2) Ukulungelelanisa ngokufanelekileyo inkqubo yezobuchwepheshe.

Oku ngasentla kuyindlela yokunciphisa impazamo ye-workpiece, kwaye ukulungelelaniswa okufanelekileyo kwenkqubo kunokuphucula ngokufanelekileyo ukuchaneka komsebenzi.

Okungakumbi malunga nesi sicatshulwa somthomboUmbhalo onguvimba ofunekayo ngolwazi olongezelelweyo loguqulo

Ukuzisa impendulo

Iiphaneli ezisecaleni

Imbali

Igciniwe

Yiba negalelo

2. Ukusetwa okufanelekileyo kweendlela zokusebenza

Ukusetwa okunengqiqo kwendlela yokucubungula kunye nolandelelwano lokucubungula sisiseko esibalulekileyo sokuphucula inkqubo yokucubungula i-workpiece.Inokuthi ithathelwe ingqalelo kwinkalo yendlela yomatshini kunye nendlela yokutya.

Xa uqhuba i-CNC yokugaya i-workpiece, kuyimfuneko ukukhetha indlela efanelekileyo yokutya ngokweemfuno zeteknoloji ye-workpiece ukuqinisekisa ukuchaneka kokusika kunye nokusebenza kakuhle kwe-workpiece.Xa ukugaya i-contour yangaphandle ye-workpiece yendiza, iindlela zokusika kunye nokusika kwesixhobo kufuneka zilungiswe.Zama ukusika ngaphakathi nangaphandle ngomgca wolwandiso lwegophe lecontour ukuphepha iimpawu zeemela kwindawo yokuhlangana.Ngexesha elifanayo, kwinkqubo yokugaya, ukugaya phantsi okanye ukunyusa kufuneka kukhethwe ngokwemeko ye-workpiece.

3. Ukukhetha isixhobo kunye nofakelo oluchanekileyo

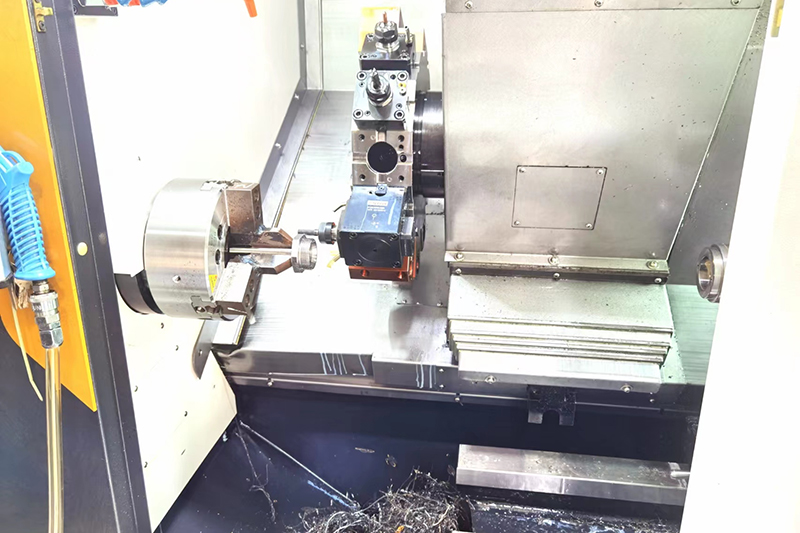

Ingaba i-CNC machining okanye i-machining eqhelekileyo, isixhobo sisebenza ngokuthe ngqo kwi-workpiece, ngoko ke ukukhethwa kwayo kunye nofakelo zizinto ezibaluleke kakhulu zokuchaneka komatshini kunye nomgangatho womphezulu we-workpiece.Ngokukodwa xa i-workpiece icutshungulwa kwiziko lomatshini le-CNC, izixhobo zigcinwa kwiphephancwadi yesixhobo kwangaphambili, kwaye emva kokuba i-process iqalile, ayikwazi ukutshintshwa ngokuthanda.Ngoko ke, umgaqo jikelele wokukhethwa kwesixhobo kukuba: ukufakwa lula kunye nokulungelelaniswa, ukuqina okulungileyo, ukuqina okuphezulu kunye nokuchaneka okuphezulu.

4. Ukhetho olufanelekileyo lwexabiso lokusika

Ukuzimisela kwexabiso lokusika liyinxalenye ebalulekileyo yenkqubo yomatshini we-CNC.Ubungakanani bayo buyiparameter ebalulekileyo yentshukumo ephambili kunye nentshukumo yokutya yesixhobo somatshini, kwaye inefuthe elibalulekileyo ekuchanekeni komatshini, ukusebenza kakuhle komatshini kunye nokunxiba kwesixhobo somsebenzi.Ukukhethwa kwexabiso lokusika libandakanya isantya sokusika, ukubuyisela umva kunye nemali yokutya.Umgaqo osisiseko wokukhetha kukuba: xa ukuqina kuvumela, ubunzulu obukhulu bokusika busetyenziselwa ukukhwabanisa ukunciphisa inani lokupasa kunye nokuphucula imveliso yomsebenzi;ubunzulu obuncinci bokusika busetyenziselwa ukugqiba ukufumana umgangatho ophezulu womphezulu.

Ixesha lokuposa: Sep-26-2022